Ever wonder how products go to shelves on display in stores? How do services deliver smoothly? It is a meticulous thing called Supply Chain – thanks to this we all enjoy everything we can purchase.

But what ensures their delivery and quality is called Supply Chain Management. It oversees the entire process from supply sourcing to market itself.

The whole supply chain operation can be tricky, especially around the delivery of the product or service to the consumers.

Everything between the entire process involves a lot of organizations and resources. Plus, heaps of emerging technologies. Supply Chain Management then becomes a pivotal initiative for companies.

How Important Is Supply Chain Management

Before delving into the nitty-gritty of Supply Chain Management or SCM, we have to know what it actually is.

It may be a big component of heaps of companies around the world but to put it simply it is the monitoring of all the activities involved in the supply chain. It guarantees the smooth flow of goods and services all the way to the market and consumers.

SCM allows companies and businesses to run supply chains for their product in the most efficient way possible. It also upholds quality and maximizes customer value.

Supply Chain flow involves several entities and processes in between, so errors are more likely to happen. SCM acts as the supervisor that ensures no errors occur. They also aim to maintain the efficiency and productivity of the entire chain.

How Does SCM Work?

Most companies have an SCM manager to oversee the entire chain, control it, and make the necessary decisions that will link all the processes. SCM’s principle is to deliver the product or service to the market with the idea that it is the result of the various efforts of the entities and activities involved.

From sourcing the material to production, shipment, and market distribution. This adds to the value of the company’s operations.

A traditional SCM system has five basic components:

Planning

The first step in the supply chain management process is to plan how to satisfy consumer expectations for a good or service. Here, you can start to prepare and manage all resources required to meet such demand. After a demand is determined or an order is placed, the supply chain can then be established.

Planning also includes developing measures to assess the supply chain’s efficiency. It also guarantees that it has the capacity to satisfy consumer demands while achieving the company’s objectives.

Sourcing

After the planning phase, you can then determine the raw materials or services needed. These components are needed to manufacture a product and the suppliers that provide them. Being able to find the perfect supplier is a critical part of the entire supply chain.

Here, you can also establish processes that allow you to oversee and manage relationships with the given suppliers. Most of it involves creating contracts that manage new suppliers and look after existing ones as well.

Manufacturing

After determining the suppliers, processes, and relationships, manufacturing takes place. This involves reviewing and accepting raw materials, manufacturing, quality testing, and packaging.

Overseeing the entire process of manufacturing allows the company to ensure quality and production output. This helps companies to guarantee quality standards are sustained.

Delivering

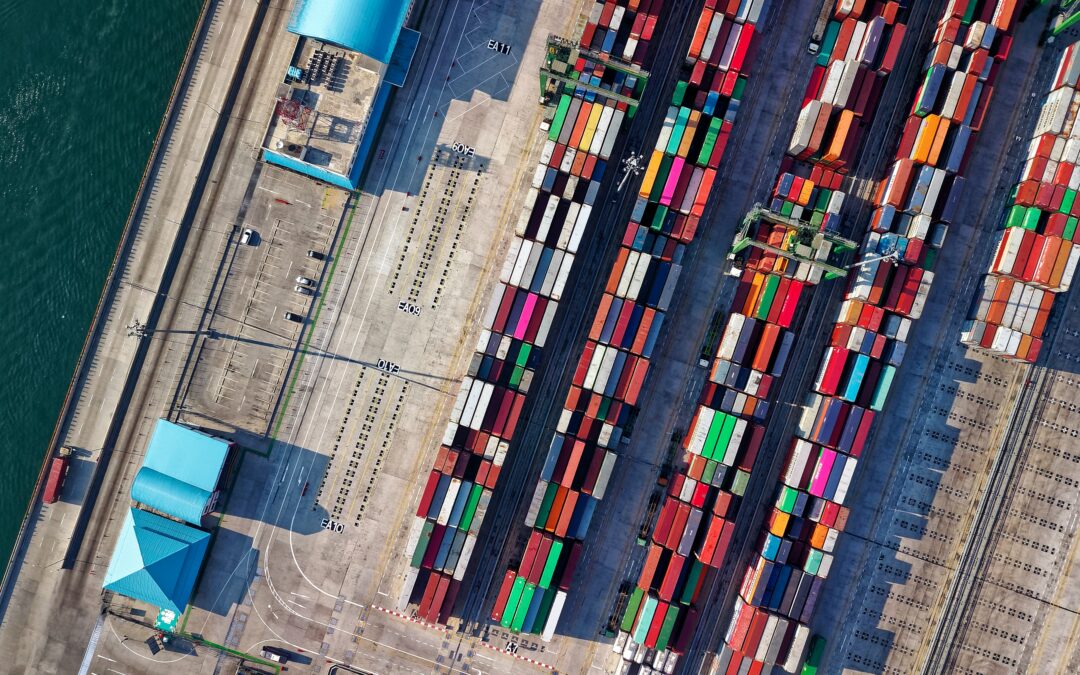

After manufactured products are packaged, delivery then follows. The delivery component involves distribution and logistics. This makes sure the product gets to the market and reaches the customer.

A Supply Chain Manager coordinates customer orders, schedules deliveries, and dispatches loads. They also invoice customers and receive payments. Some companies outsource delivery to other organizations or other entities. Logistics are often challenging because some products are manufactured overseas. This often involves shipments and trucking.

Returning

However, the act of supply chain management doesn’t end at product delivery. Supply Chain Managers also need to create a system that supports the return of products.

Returning is the creation of a network or process that takes back defective products. This prompts re-evaluation, re-production, or even scraping of a product altogether. This should be able to cater to and support customer needs.

The supply chain is a vital part of the operation of a company or business, its nature can be quite complicated and requires careful attention. Supply Chain Management can streamline and make its components manageable despite the challenges. So the next time you take a look at a product you want, you can easily assume it went through a meticulous process that ensures its quality. If anything, that gives you a breath of relief.

Recent Comments